To choose an air compressor that meet your needs, there are some key points for you to consider:

pressure, air discharge volume, power supply, environmental protection, installation type , cooling types, noise level, control system, required efficiency, etc.

Our air compressor expert will explain to you step by step as followings:

Key Point 1: Pressure

Air compressor’s discharging air pressure (kg/cm²) :

In addition to consider the actual pressure used as a benchmark, you also need to add the pressure loss of the air flowing through pipes and the purifying system.

Pressure drops inside the pipes:

The pressure loss of compressed air in the pipes is like a car driving on the road. When the road is wide and straight, it can speed up and reduce the loss of energy. Generally, the loss of air pressure inside the pipes is about 0.5 kg/cm². Besides, the compressed air usually needs to be processed by the air purifying system, heat exchanger, dryer and will cause other pressure drops, which are about 0.3 ~ 0.5 kg/cm².

Key Point 2: Free Air Delivery ( F.A.D) and Displacement

It is important to understand the difference between the F.A.D and the

displacement.

F.A.D :

Use the required instruments and equipment to measure the air discharge volume of the air compressor by the standard detecting method.

Displacement:

Also known as theoretical displacement. The value is derived from the calculation

based on the theory that ignores mechanical energy loss and efficiency factors.

Generally, to obtain the F.A.D value, for single-stage compression, the displacement value will be multiplied by 0.65, and for two-stage compression, it will be multiplied by 0.8 .

Therefore, decision of the air discharge volume should consider the following points:

A:)Current required (100%)

B:)Possible pipe leakage (10%)

C:)Future expansion plan (20%~50%)

D:) Allowable margin (10%~30%)

Hence, the total required air discharge volume = (A+B+C) x (1+D), when the value of C is larger, the value of D can be reduced. Pay special attention to the fact that

the measurement standard is based on the "actual air discharge volume".

Key Point 3: Power Supply

Regarding to the power supply, the motor used for an air compressor can be either single-phase or three-phase.

Single-phase:

The general power voltages are 110V and 220V. For your safety and convenience, compressors under 1HP can use 110V. Compressors over 1HP can use 220V. Compressors of 5HP and above are not suitable to use a single-phase power supply.

Three-phase:

The general power voltages are 220V, 380V, and 440V. Three-phase motors are typically used in compressors with higher HP.

Countries around the world have different power supplies, different voltages, different frequencies and different electrical regulations. When purchasing an air compressor, you must specify the voltage, frequency, and the number of phases used, so that the manufacturer can correctly assemble the air compressor with the electrical control equipment of the machine. Before you use the air compressor, it is necessary to confirm that the power voltage matches with the one displayed on the nameplate of the compressor motor.

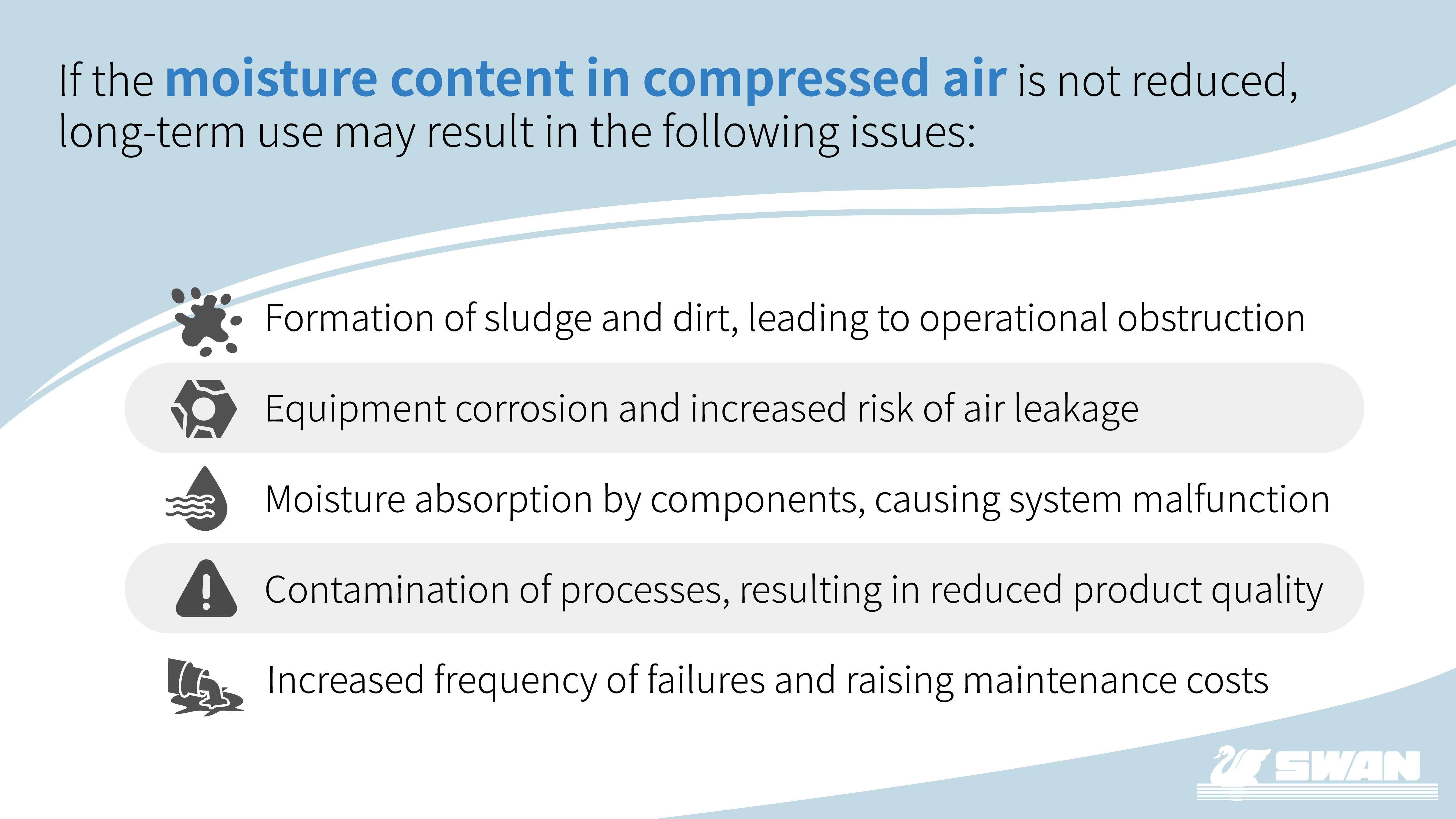

Key Point 4: Environmental Protection requirements

According to different interior structures and designs, air compressors can be divided into the oil-lubricated type and the oil-less type. Users can choose between them according to their actual needs of the work.

Oil type:

An air compressor that uses lubricating oil to lubricate the rotating and compressing parts inside it, is called oil type. The compressed air will contain a small amount of oil but it is still suitable for general industrial use. A filter can be installed to remove excessive oil if needed. Usually, after a new machine has been running for certain hours, the oil must be replaced completely, thereafter, it must be replaced regularly. If you fail to replace the oil regularly or an improper lubricating oil is selected, it will cause damage to the internal parts of the air compressor. Please refer to the manual for the correct selection of lubricating oil and the interval of regular replacement. Applicable industries: steel, plastics, mold, machine shops, and general manufacturing factories.

Oil-less type:

The oil-less compressors are made of special self-lubricating materials, and the lubrication of the compressing parts can be achieved without the use of oil. Therefore, there is no oil in the compressed air, which can meet the oil-free requirements in industries like the precision industry, medical industry, food manufacturing, semiconductor industry, coating and other industries. The oil-less air compressors are without the problems of waste oil and oil pollution.

Key Point 5: Installation

Based on different usage types, you can choose:

Mobile type:

Small air compressors are all mobile, using two or four wheels to facilitate their mobility as required.

Fixed type:

Larger air compressors are not easy to be moved due to their heavy weight, the need to be equipped with fixed piping and to reduce vibration and noise, therefore, most of them have to be installed fixedly. Pay attention to the fixing strength and the leveling of the machines during installation.

Key Point 6: Cooling Types

The cooling functions can reach the followings:

1. Lower down pump temperature, extend machine’s life and reduce oil content in the compressed air.

2. Reduce discharged air temperature and improve the drying efficiency of compressed air.

3. Provide safety protection and prevent dangers caused by overheating.

Cooling types of air compressors:

Water-cooled:

A circulating cooling water tower must be installed. By using cooling water flow to achieve heat exchange between the cylinder and the exhausting air is an extremely efficient heat dissipating method. It is suitable for larger horsepower models.

Air-cooled:

Using the cooling airflow generated by the cooling fan to achieve the heat exchange between the cylinder and the exhausting air. It is a simple designed heat dissipating system. Recently, with its efficient circulating airflow design, it has become a popular cooling system for both large and small horsepower models.

Recommendations for the installation space of the air compressor:

Good ventilation and sufficient space should be the first priority. In the configuration position of the machine, the distance between the cooling fan of the Piston compressor and the wall should be at least 30cm or above. For screw air compressors, the distance between the air exhausting port surface and the wall should be at least 1m, and the distance to the roof from it should be at least 1.5m.

Key Point 7: Noise Level Requirements

The noise of an air compressor usually comes from the followings:

- The operation of the body: during the compressing process, the mechanical impact sound in rapid running, the sound of airflow, the sound of rubbing between parts, and the noise of the cooling fan running.

- Power source generation: the running noise generated by the electric motor or engine to drive the air compressor .

- Unbalanced compressor body: poor balance correction or installation without leveling will cause the body and metal covers to vibrate and make noise.

- Exhausting air leakage: the leakage of exhausting air and the high-pressure gas flow will cause noise. Due to different operations and structures, the noise levels could be different.

- Open-type reciprocating air compressors: the noise from the reciprocating movement of the piston is not blocked, and it will spread to the environment along with the sound waves. Small horsepower has low noise and will not affect the environment, but higher horsepower is noisy and must be handled appropriately.

- Cabinet-type reciprocating air compressors: although the compressor body of the cabinet type is the same as the open-type model, the sheet metal covers are specially designed, using high-grade sound-absorbing materials, shock-proof materials, together with the special design to block and insulate sound sources, altogether will reduce considerable vibration and noise.

- Rotary screw air compressor: Due to the different operating mode of the rotary screw air compressor from that of the reciprocating air compressor , the noise produced is different. The rotary screw type is usually with the cabinet-type design. Its sheet metal covers use high-grade sound-absorbing materials, anti-vibration materials, together with the special design to insulate sound source, so its noise value is usually lower than the reciprocating type.

The noise prevention does not mean to achieve a no-noise condition, but to reduce the excessively high noise level to an acceptable working environment noise level. Generally, it is required to be below 75 dBA. Based on economic conditions consideration , when environmental restrictions are not required so seriously, the open models are your wise choice. The cabinet type models will be recommended when the quality of life and work environmental restrictions are highly demanded.

Key Point 8: Control System

The control system of the air compressor should be properly selected and arranged according to different application conditions and required discharged air quantity, to maximize the compression performance and mechanical life. Taking air-cooled type compressors as an example, our currently used control methods are semi-automatic control and fully automatic control.

Semi-automatic control: Use the automatic unloading system to control the operation of the air compressor. Its operating procedure is that when the air pressure reaches to its upper limit, the automatic unloading system drives the unloader piston to keep the intake valve open and running under the un-loading state.

Fully automatic control: Use the pressure switch system to control the motor operation. When the air pressure reaches to its upper limit of the pressure switch, the switch turns off and interrupts the motor power supply to stop the air compressor running. When the pressure drops to its lower limit, the switch turns on the motor power supply and the air compressor returns to run and resume compressing air. This control method is suitable for intermittent air supply and for small horsepower compressors.

In the actual operation of the control system, the following methods can provide more flexible applications.

Recommendations:

Full/semi-automatic selection control--- establish a control system to select the control method according to the actual situation.

Full/semi-automatic conversion control --- use the microcomputer control system to select the control mode automatically according to the operating conditions.

The control system of screw-type or large machine can be more diverse, we will explain it in another article later.

Key Point 9: Efficiency required

Different types of air compressors have their own preferred efficient running areas with regards to different structural design, operating pressure, displacement, and the number of compression stages:

Lower pressure and lower horsepower -- mainly choose the reciprocating type air compressors.

For compressors below 10HP and demand for a silent environment, you can choose either scroll type or cabinet type.

For above 20HP compressors: mainly choose rotary screw type or water-cooled type compressors.

For pressure above 12kg/cm2 compressors: two-stage compression, high-pressure reciprocating air compressor would be the best choice.