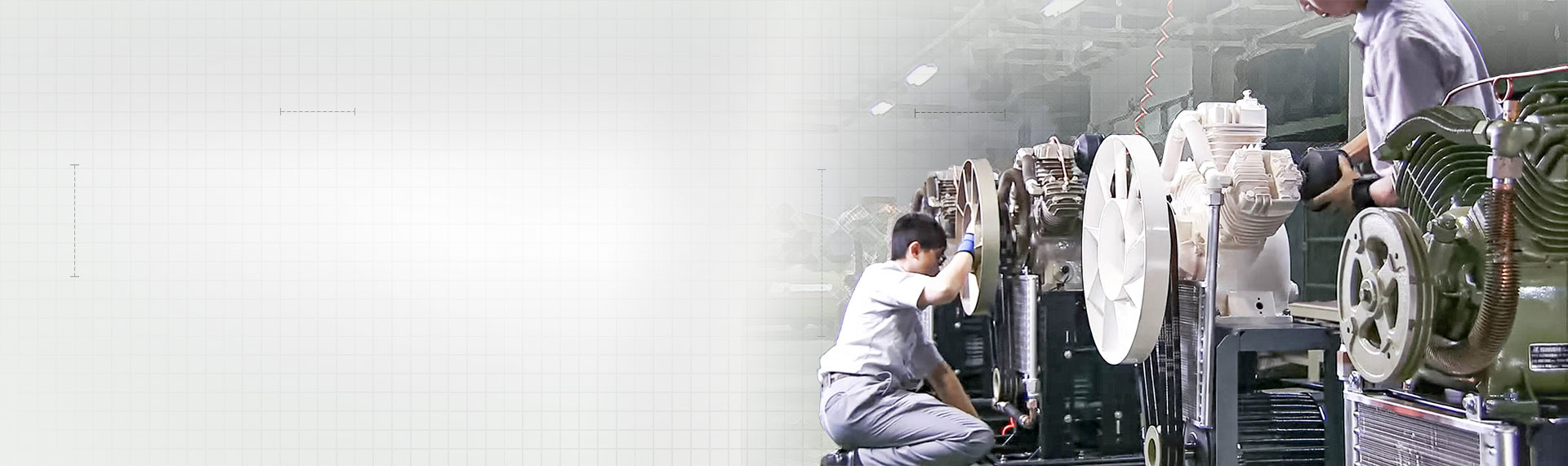

Why SWAN?

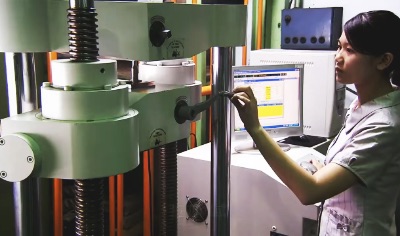

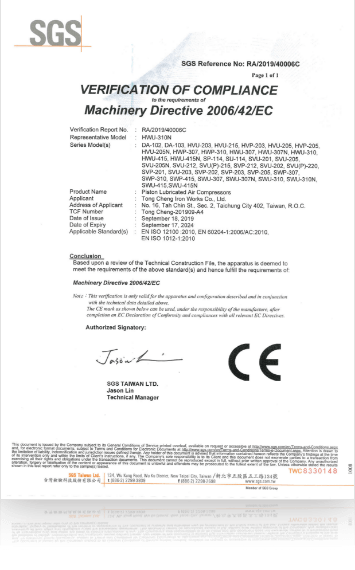

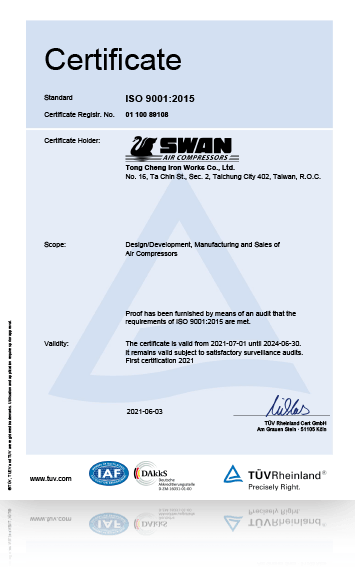

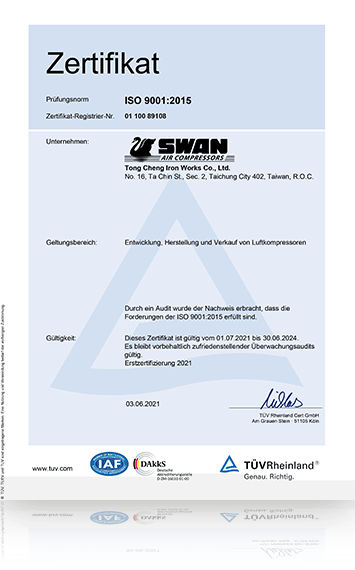

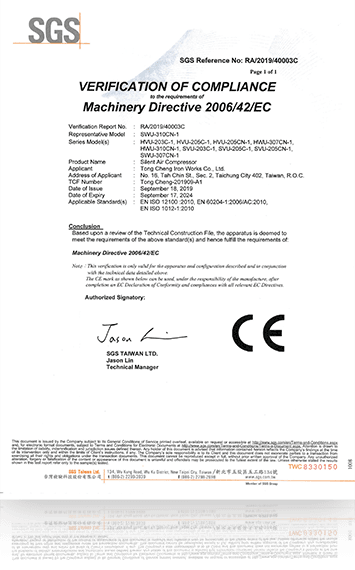

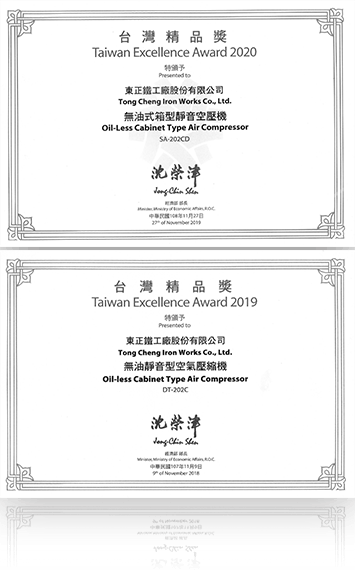

SWAN has the most professional R&D team, with multiple production bases, processing and assembly plants, and sole proprietorships all over the world. In terms of after-sale services, our dealers’ service network is spreading all over the world. With more than half century of operating experiences, SWAN has accumulated considerable technical energy and combined them with modern new creative ideas. Not only effectively apply industry experiences to shorten the product development time, we also use advanced technology and sophisticated equipment to develop various products to meet the special requirements from our ODM and OEM customers. Moreover, our manufacturing process is fully complying with the ISO9001 quality assurance regulations, which can ensure to supply our customers with highly reliable air compressors.