Why does compressed air contain moisture, and what problems may occur when using compressed air with moisture?

In industrial production lines, compressed air is an indispensable source of power for many manufacturing processes. However, many users have reported that compressed air unexpectedly “produces water,” which can even lead to tool jamming and failure, paint surface granulation, or abnormalities in product quality. These irregular conditions may be related to untreated moisture present in the compressed air.

The atmosphere naturally contains moisture. After being compressed by an air compressor, the air volume decreases and temperature changes cause water vapor to condense first in the compressor’s cooler and air receiver tank. When the compressed air is delivered to low-temperature environments or pipelines, further temperature changes affect the saturated moisture content of the air, causing additional condensation. The condensed water may then be carried along with the airflow into production equipment or become mixed into the products.

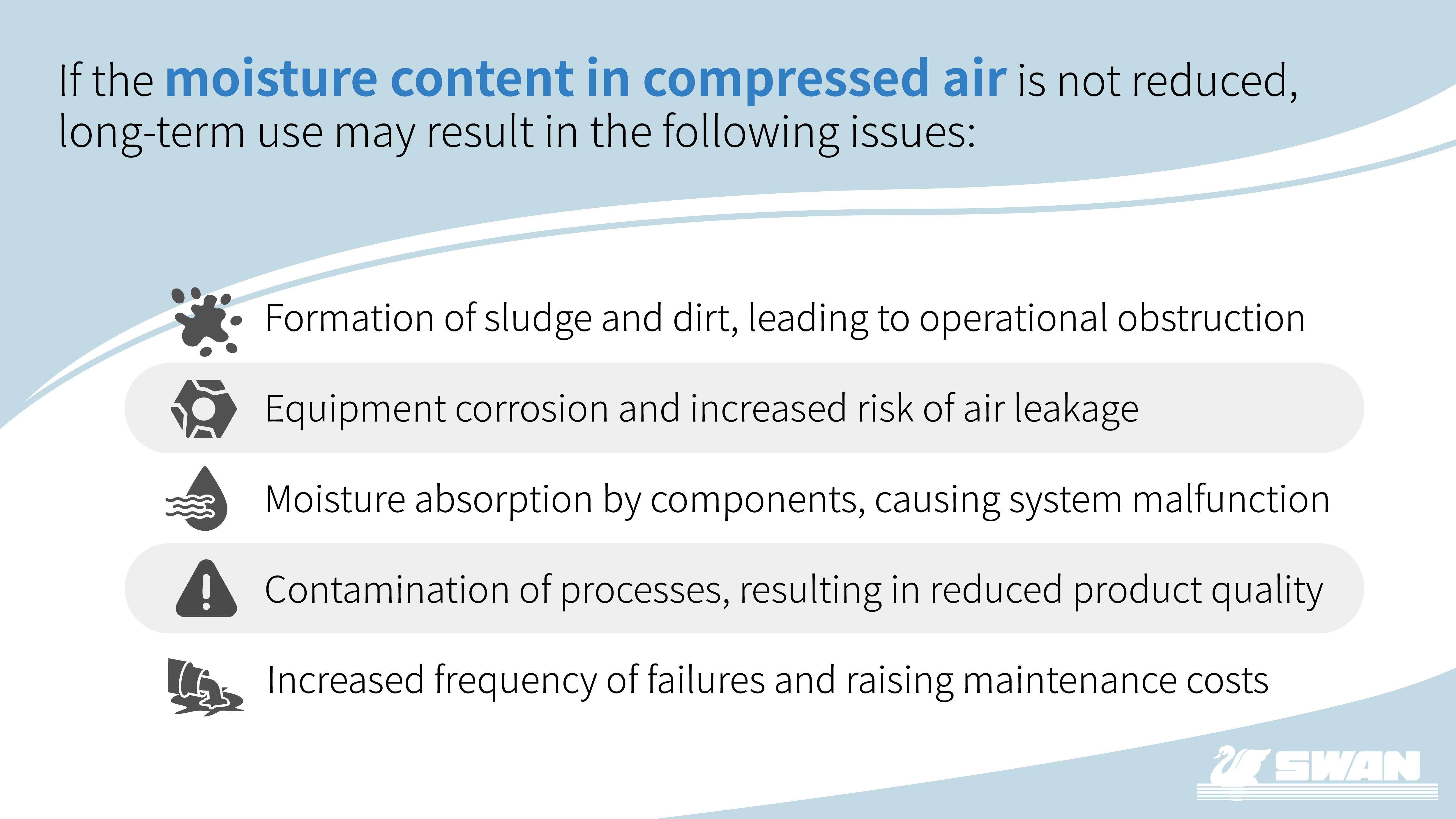

If the moisture content in compressed air is not reduced, the following problems may occur over long-term use:

1. Mixed with impurities, moisture forms sludge that causes pneumatic components to seize or cylinders to stick, reducing operational efficiency.

2. Moisture leads to corrosion of equipment and pipeline metal parts, generating additional contaminants and causing seal failure and air leakage.

3. Condensed water causes electrical control and sensing components to absorb moisture, resulting in system malfunctions or failures.

4. Condensed water contaminates production processes, affecting coating quality or altering cleaning and spraying performance.

5. Increased frequency of component failures, indirectly raising operational and maintenance costs.

Compressed Air Purity Class: ISO 8573-1:2010

| Solid particles — Particulate concentration (cn/m³) | Moisture and Water Content | Oil Content | |||

| The maximum number of particles with a particle size d (μm) allowed per 1 m³. | Pressure Dew Point | Concentration | |||

| 0.1≤d≤0.5μm | 0.5≤d≤1.0μm | 1.0≤d≤5.0μm | ℃ (℉) | mg/m³ | |

| 0 | Note: Stricter requirements than Class 1 may be specified according to customer needs or supplier agreements. | ||||

| 1 | ≤20,000 | ≤400 | ≤10 | ≤70(-94) | ≤0.01 |

| 2 | ≤400,000 | ≤6,000 | ≤100 | ≤40(-40) | ≤0.1 |

| 3 | - | ≤90,000 | ≤1,000 | ≤20(-4) | ≤1 |

| 4 | - | - | ≤10,000 | ≤+3(+38) | ≤5 |

| 5 | - | - | ≤100,000 | ≤+7(+45) | >5 |

| 6 | - | - | - | ≤+10(+50) | - |

Before discussing the moisture content in compressed air, it is essential to first understand the compressed air purity standard ISO 8573-1.

According to ISO 8573-1, compressed air purity classes are defined based on three major parameters: solid particles, water (humidity and liquid water), and oil (total oil – liquid, aerosol, and vapor). The classification is determined by the concentration of these elements present in the compressed air.

For example, when compressed air purity is required to meet ISO 8573-1 Class 2,5,2, it means that both solid particles and oil must be treated with filtration equipment to comply with Class 2 requirements, while an air dryer must be used to control the moisture content to meet the Class 5 standard.

In industry, it is widely recognized that excessively moist or contaminated compressed air poses risks and potential damage to both equipment and products. However, determining how to select the appropriate air purification and air dryer equipment according to specific applications has become very significant in modern manufacturers.

Introduction to the Functions and Main Types of Air Dryers

The core purpose of an air dryer is to reduce the moisture content in compressed air, ensuring stable air supply quality. In general, air dryers on the market can be categorized into the following two main types:

1.Refrigerated Type Air Dryer

The refrigerated air dryer is currently the most common type of compressed air-drying equipment used in the industrial field. Its working principle involves cooling the compressed air, which changes its saturated moisture state and causes the water vapor to condense into liquid droplets. These droplets are then separated and discharged, thereby achieving the dehumidification effect.

To balance dehumidification efficiency and prevent pipeline freezing, most brands on the market operate with an actual heat exchange temperature ranging between +2°C and 15°C under normal conditions. Through proper equipment selection and effective management of airflow, pressure, and ambient temperature, it is possible to design a system that meets the ISO 8573-1 moisture content Class 4 to Class 6 requirements.

*The outlet pressure dew point ranges from approximately 2°C to 15°C, and the system can be designed and configured according to the required class for use in general industrial applications.

*Applicable industries: cleaning and packaging applications, general manufacturing, automotive maintenance, woodworking, plastic molding, general painting/coating processes, and as pre-treatment air sources for nitrogen generators and adsorption-type air dryers.

*Advantages: simple structure and easy configuration; when equipped with a no-loss drainer, it eliminates air consumption during the drying process.

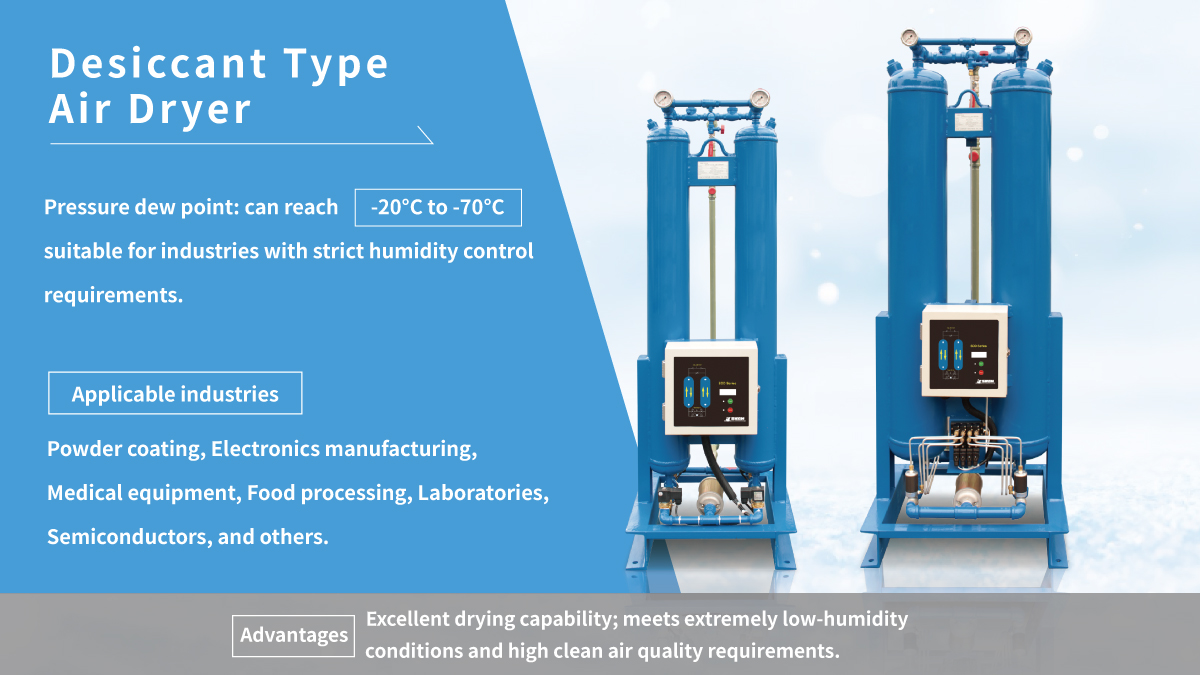

2.Desiccant Type Air Dryer

When the compressed air treated by a refrigerated air dryer is still insufficient to meet the dryness requirements of the production line, an adsorption air dryer is commonly used as an enhanced treatment device.

Its working principle relies on adsorbents such as molecular sieves or activated alumina, which operate in a twin-tower alternating adsorption and regeneration cycle to continuously supply highly dried compressed air.For example, according to ISO 8573-1 moisture content Class 2, the corresponding moisture level is approximately 0.024 g/m³ or lower.

However, depending on the brand design and specified moisture class, an adsorption air dryer may require up to 20% of the airflow for desiccant regeneration. This represents a significant energy cost, as the compressed air itself is produced through energy-intensive processes.

To reduce compressed air consumption, system designs often adopt a hybrid approach — using a refrigerated air dryer for overall system drying, while installing adsorption air dryers only at critical production lines where higher air dryness is required.

*Pressure dew point: can reach -20°C to -70°C, suitable for industries with strict humidity control requirements.

*Applicable industries: powder coating, electronics manufacturing, medical equipment, food processing, laboratories, semiconductors, and others.

*Advantages: excellent drying capability; meets extremely low-humidity conditions and high clean air quality requirements.

The following lists the common applications across various industries and the recommended types of air dryers for each industry:

| Industry type | Commonly configured models | Illustration |

|---|---|---|

| Traditional Machining and Hardware | Refrigerated Type Air Dryer | A basic drying process is enough to prevent rust and equipment failure. |

| Woodworking and Auto Repair | Refrigerated Type Air Dryer | Eliminate moisture at the tool end to maintain stable performance. |

| Food Processing and Packaging | Refrigerated Type Air Dryer/ Desiccant Type Air Dryer | Choose based on the cleanliness level required by the process. |

| Electronics and Optoelectronics | Refrigerated Type Air Dryer + Desiccant Type Air Dryer | Prevents component corrosion and static problems caused by moisture. |

| Medical and Laboratory | Refrigerated Type Air Dryer + Desiccant Type Air Dryer | The air quality must meet high cleanliness and moisture-free standards. |

| Semiconductor Process | Refrigerated Type Air Dryer + Desiccant Type Air Dryer | Requires air quality compliant with ISO 8573-1 Class 1 standard. |

If there are no specific application requirements, a refrigerated air dryer is generally a suitable starting point for most factories. As operational needs expand, an adsorption dryer system can later be evaluated and upgraded accordingly.

With proper dryer configuration, it is possible to significantly extend the lifespan of the compressed air system, reduce maintenance frequency, and improve overall air quality and production stability.

SWAN air compressor and air dryer suggestion & recommendation

![]()

In practical applications, the selection of an air dryer is not determined by a single factor. It requires careful consideration of multiple elements, including the operating environment, compressor configuration, air quality standards, and budget balance. With our extensive practical experience in the compressed air industry, we can provide customized solutions tailored to the specific needs of different industries

* Air dryer type selection suggestion

* Complete Compressed Air System Setup

* On-site Assessment and System Optimization Services

Interested in finding the best air dryer and compressor solution for your needs? Contact SWAN Air Compressors today—we’ll help you design a smarter, more efficient, and more reliable compressed air system.

.jpg)