SWAN In Hannover Messe 2025

Your Partner for Industrial Compressed Air

SWAN Air Compressors cordially invites you to visit our booth and explore efficient, eco-friendly compressored air solutions. Discover our innovative technologies, diverse products, and connect with our professional team to enhance performance and drive sustainable development. We look forward to shaping a greener future with you!

Visit our booth at Hall 12 Stand E34 to check out new products!

.jpg)

Products at Hannover Messe 2025

.png)

BSD-430-40K Oil-less Air Booster

| Power | F.A.D. | Inlet Pressure |

Working Pressure |

|---|---|---|---|

| 30 HP | 2,666 l/min @ inlet 7 kg/cm² |

5~7 kg/cm² | 40 kg/cm² |

- Intakes pressure air at 5~7 kg/cm² and boosts to max. 40 kg/cm² to meet various manufacturing demands.

- Air cooled design saves additional power consumption and eliminates the cost of building a water cooler system.

.png)

SKR-02D Scroll Air Compressor

| Power | F.A.D. | Working Pressure | Noise Level |

|---|---|---|---|

| 2 HP | 160 l/min | 8 kg/cm² | 60 dB |

- Direct drive design increases transmission efficiency and reduces unnecessary power loss.

- Robust compact cabinet ensures noise is below 60dB and suitable for indoor installation.

*Flexible option: with or without air dryer

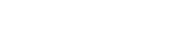

SDU-310 Oil-less Pump

| Power | F.A.D. | Working Pressure |

|---|---|---|

| 10 HP | 885 l/min | 8 kg/cm² |

- Equipped with Ni-SiC electroplating cylinder

- Horsepower ranges from 3HP to 15HP.

.png)

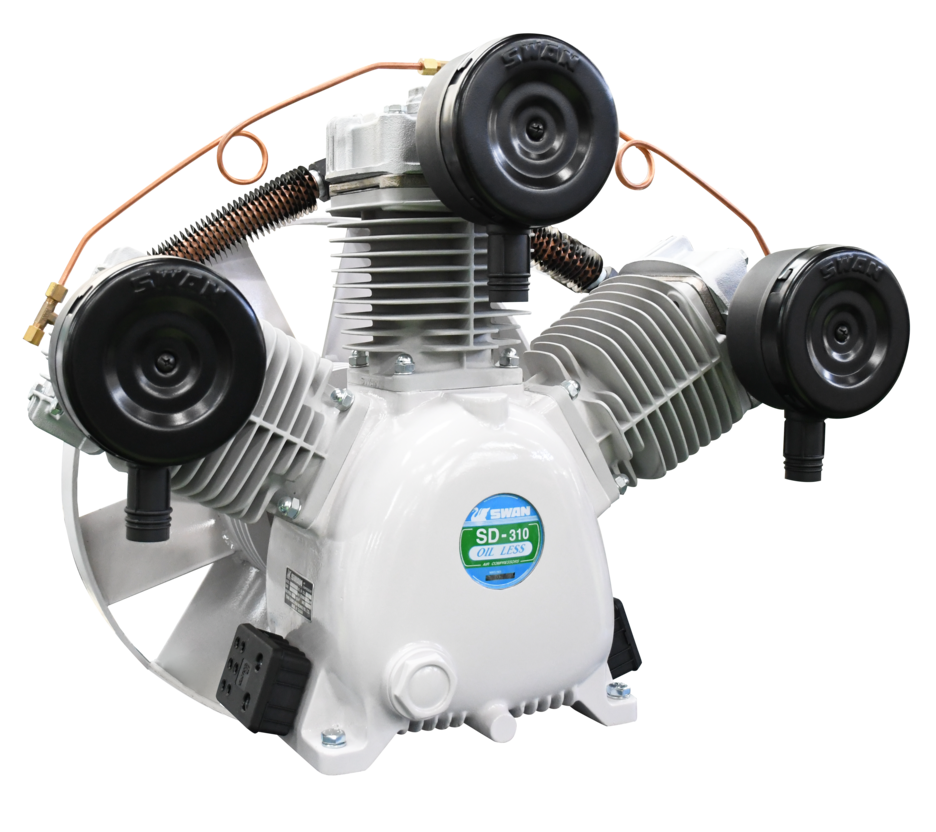

SDU-310D Oil-less Pump

| Power | F.A.D. | Working Pressure |

|---|---|---|

| 10 HP | 875 l/min | 8 kg/cm² |

- Direct drive design and equipped with Ni-SiC electroplating cylinder.

- Motor options: induction motor or permanent magnet motor (IE4 rated and 30% smaller in size) pairs with inverter.

.png)

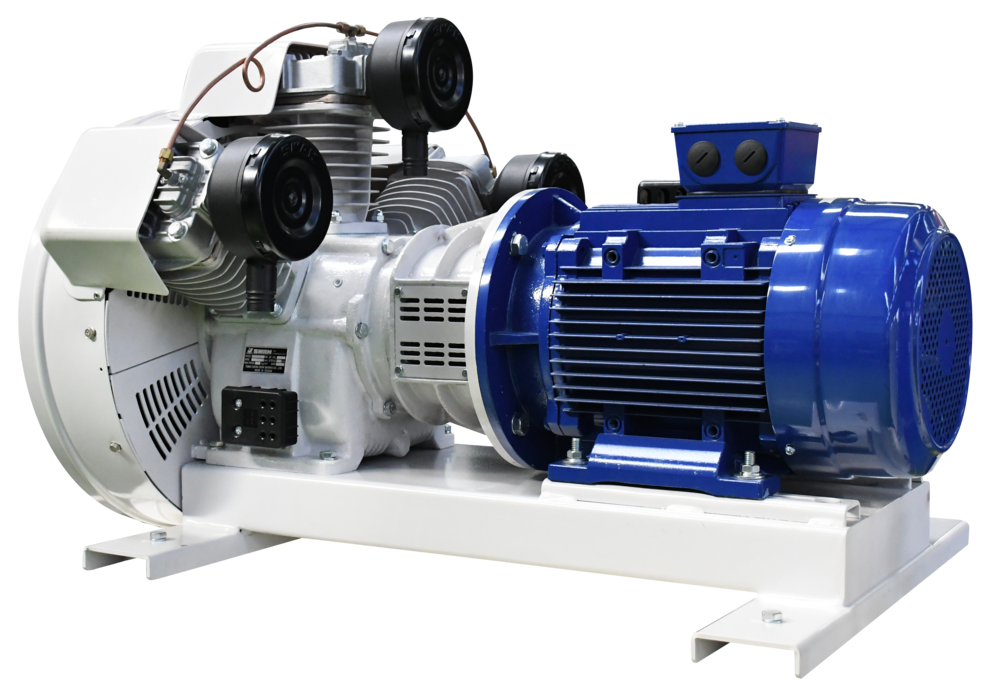

BSD-210 Oil-less Air Booster

| Power | F.A.D. | Inlet Pressure |

Working Pressure |

|---|---|---|---|

| 10 HP | 2,400 l/min | 2~5 kg/cm² | 10 kg/cm² |

- Intakes low pressure air (2 ~ 5 kg/cm²) in the pipeline and boosts to max. 10 kg/cm² to meet manufacturing demands and allocate pressure efficiently to save power.

- 7.5% energy is conserved if every 1kg/cm² decrease in working pressure. Lowering the pressure of main system to 6~7 kg/cm² and install a booster to operate high pressure applications.

Product Features

Nickel Silicon Carbide Electroplating Cylinder

Electroplated with a composite of nickel and silicon carbide, the inner walls of the aluminum alloy cylinders have enhanced hardness and the wear resistance. The electroplating treatment also extends the lifespan of components and achieves better heat dissipation.

Anti-Corrosion and Anti-Rust Treated Cylinder Head

Treated with Nai-Hsin and Nai-Te to prevent rust and the other problems that follow, such as abnormal operation noise, reduced efficiency, and serious damage to the air compressor.